top of page

Abrasive Lapping Film Application

Abrasive lapping film products are widely used in the manufacturing industry for polishing and finishing various materials, including metals, ceramics, plastics, and composites. These films are made of a flexible polyester backing that is coated with abrasive particles, such as diamond, aluminum oxide, or silicon carbide.

The abrasive particles are evenly distributed on the surface of the film, ensuring consistent and precise results. The films come in different grades, from coarse to fine, to accommodate different polishing needs. The coarse grades are used for removing scratches and surface imperfections, while the finer grades are used for achieving a mirror-like finish.

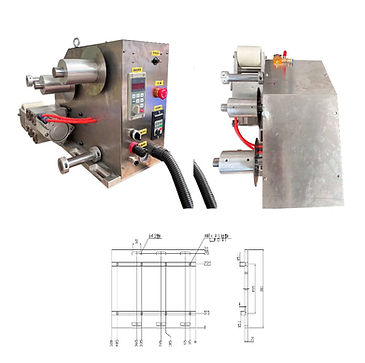

Abrasive lapping films are easy to use and require minimal setup and maintenance. They can be used with a variety of lapping machines and tools, including flat lapping machines, rotary lapping machines, and hand lapping tools. The films are also compatible with different types of lubricants, such as oil, water, and diamond suspensions.

One of the advantages of using abrasive lapping films is that they provide a consistent and repeatable finish. This is important in manufacturing applications where consistent quality is critical. The films also offer a high level of precision, allowing for tight tolerances and accurate surface finishes.

In addition to their use in manufacturing, abrasive lapping films are also commonly used in research and development applications, such as in the semiconductor industry. They are also used in the optical industry for polishing lenses and other optical components.

Overall, abrasive lapping films are a versatile and effective tool for achieving high-quality surface finishes. With their ease of use and consistency, they are a popular choice for manufacturers and researchers alike.

Widget Didn’t Load

Check your internet and refresh this page.

If that doesn’t work, contact us.

bottom of page